Eddy Current Slots

We produce and distribute Eddy Current Test Instruments and Systems for the North/South American and Global NDT market.

For more than 40 years we have been developing, producing and marketing eddy current instruments and systems for testing that are in use around the world today in crack, heat-treatment, positive material identification, and grinding burn tests. Testing solutions for every problem and every need. Made in the USA and Germany.

Custom solutions based on research and innovation. Close collaboration with leading labs, technology partners and in fields of applied research make it possible to develop a completely new generation of testing instruments. We use the latest components, specially developed materials, and systematically developed technologies. ROHMANN is a supplier of the most advanced and powerful testing instruments and systems currently to be found on the market.

How can we help you? We will be glad to assist you with any specific questions you may have. Simply contact us and make use of our search system or inquiry form.

EDM Slot Sizing Block, 7075-T6 Aluminum This block contains nine EDM slots from 0.100' to 0.900' deep. Slot width is 0.011'. Nominal depth is laser engraved on the side of the block.

Products News:

ELOTEST PL600 – The most avanced Eddy Current Test Instument

- Maximum stability with unsurpassed signal purity for best results with classical eddy current and harmonic analysis

- Suitable for all types of eddy current testing: Crack, heat treatment, material mix-up and grinding burn testing

- Maximum test reliability through comprehensive system and sensor monitoring

- Application-specific user interfaces for simplest operation

- Full integration through extensive I/O functions with fieldbus connection

- Modular design allows flexible expansion with easy maintenance

Eddy Current Loss Calculation

Products News:

ELOTEST PL600 – R/RC

Precise material sorting and high-resolution crack and grinding burn inspection

ELOTEST PL600/Remote, 19“/4HE

ELOTEST PL600/Remote Compact, 19“½/4HE

The innovative, fully digital eddy current platform for integration into automated systems

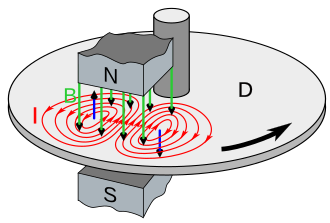

The pendulums are made of copper consisting of a 1/2' diameter rod 0.4m in length and a paddle 1/4' thick. The two are identical save for 14 slots 8mm apart cut 80% of the way up through one of the paddles (figure 1). In the slotted paddle the induced current forms smaller loops, increasing path length and therefore resistance. Eddy currents and magnetic drag. The eddy currents in the sheet of copper can be minimized by interrupting their path. A series of slots, or rectangular holes, in the copper sheet does the job very effectively (Figure 34.33). The slots interrupt possible current paths, and thus increase the resistance. The resulting current is known as Eddy current. The currents flow in a circular manner like eddies in the brook, so they are called as eddy current. They create unwanted power loss which is known as eddy current loss. Additional power is required from the supply to make up this loss; Eddy Current Concept. Eddy current is defined as the induced current on the surface of conductor in little loops or eddies due to changing magnetic flux. To better understand the concept of eddy current, let us take an example. Suppose a metallic plate is rotated in the magnetic field as shown in figure below. Lets us draw an imaginary loop on the surface of plate.

- Used with PC software under Windows or Linux or with HDMI+USB connected touch display or standard display with mouse

- Including one universal test channel module with basic license

- PL600/R, fullsize 19” rack with 15 free slots for additional modules

- PL600/RC, half size 19” rack with 6 free slots for additional modules

Eddy Current Slots Jackpot

Download the PL600 R+RC_2020 Fact Sheet (08-17-2020)